Latest News & Guidance

AIRpipe in the Press and Media.

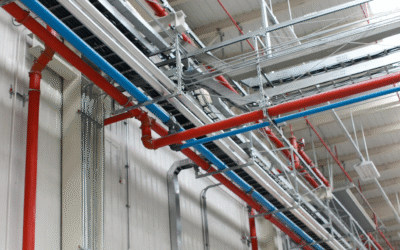

Selecting The Right Pipe For Compressed Air Systems

Why AIRpipe Aluminum Stands Out When designing compressed air systems, engineers often focus on material cost,...

Unlocking the Power of Compressed Air

The Power of Compressed Air: Unlocking The Hidden Utility Fueling Industrial Performance Imagine stepping onto your...

Compressed Air – The Hidden Backbone Of Industry

Aluminum Piping Systems: For Compressed Air, Vacuum and Inert Gases Compressed air systems quietly power productivity...

PVC VS Aluminum for Compressed Air Systems

Why PVC Is a Dangerous Gamble PVC piping may seem like a budget-friendly option for compressed air systems, but it...

Compressed Air Pipe Leaks: Causes and Solutions

The Sound Of Lost Efficiency: The Hidden Waste Beneath A Costly Utility If you’ve ever walked your plant during a...